Technology for Licensing

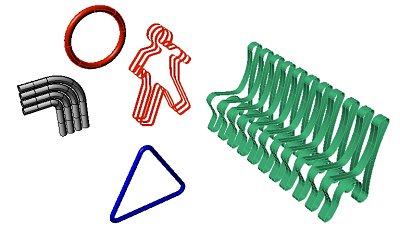

The InstaBend method (Patent Pending)

These thechnologies can be visited at www.bendtrusion.com

The InstaBend&trade method allows to continuously bend and shape thermoplastic profiles into three-dimensional objects. The method merges three processes:

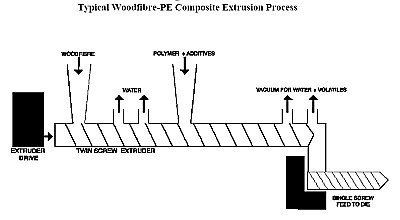

1- Recycling plastics and municipal or agricultural wastes to create Recycled Plastic Lumber RPL products

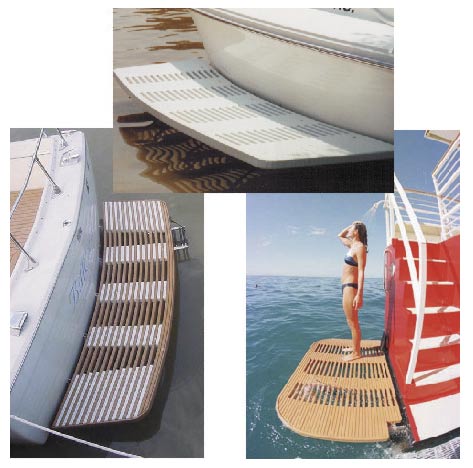

2- Use a traditional extruder to produce linear-shaped RPL products such as for decking, fencing, outdoor furniture, marine applications, etc.

3- Use the InstaBend&trade method to bend and re-shape extruded RPL products into three-dimensional objects, as profiles exit from the extruder.

Ideas For Curved Products

Plastic Lumber makes great indoor and outdoor furniture (sofa, lounge chairs, benches, trash cans...), playground equipment, etc.

Ideas for urban housing - curved structures

Plastic Lumber can be shaped, continuously, into arched structures for low-cost prefab housing - Photo and Design by Lukas Lang Building Technology

Plastic Lumber is ideal for making rounded roof trusses

First bridge structures made of Plastic Lumber

Plastic-Lumber is ideal for Marine applications..., no rotting, no splitting, maintenance-free for 50 to 100 years

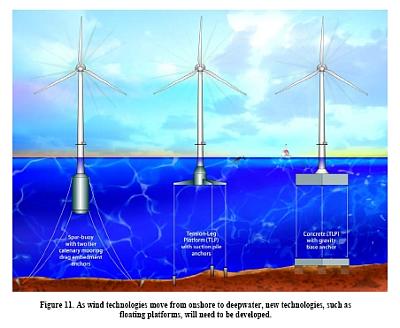

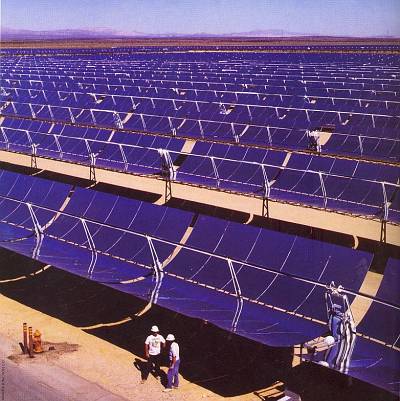

Ideas for the Energy Sector

Poles made of Plastic-Lumber can be curved or bifurcated for making cost-effective, light and durable electrical poles, street lights or all kinds of supports

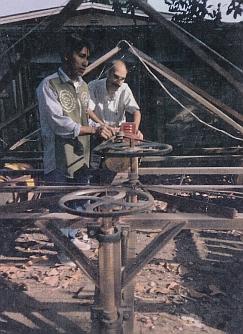

Plastic Lumber poles can reduce costs of windmills

Plastic Lumber is ideal for marine applications including poles for floating windmills

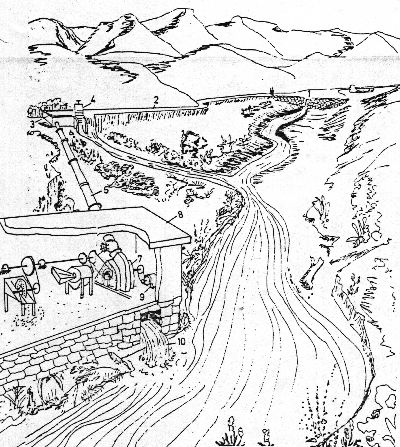

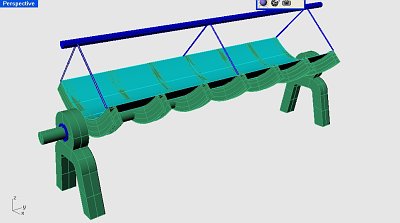

As demand for clean energy sources increases, demand for maintenance-free components made of Plastic Lumber (in green) also increases - for example many components for solar troughs can be made of Plastic Lumber (drawing not to scale).

Ideas for industrial applications

Plastic Quadro-pipe Elbow