Local Turbine Manufacture

Note: this page is still under construction. If you have trouble viewing the videos, the photos below provide an overview.

This set of videos shows planning of a hydropower system, manufacturing a turbine, digging water channels, installing the penstock, and using the hydropower for grain milling.

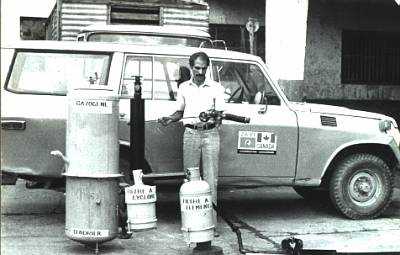

* Interview with Soheyl (in French)

* Planning a micro hydropower site

* Turbine manufacturing: wmv or mpeg format

* Water channels

* Penstock

* Hydropowered grain milling

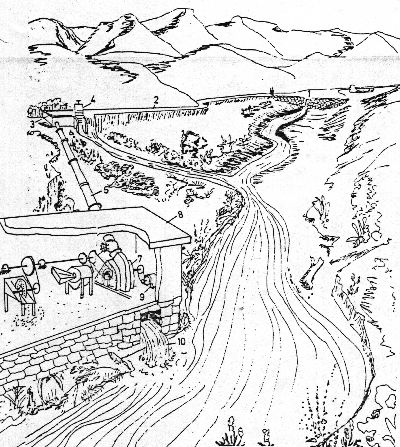

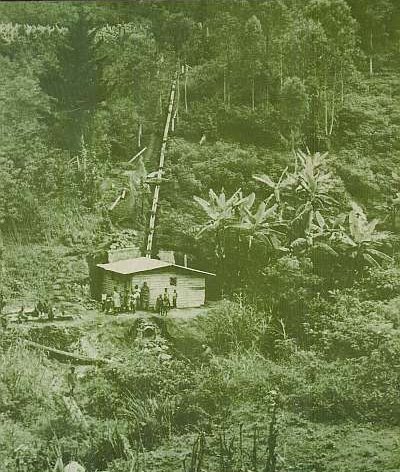

Planning a micro hydropower site

Surveying the site and designing canals

Designing the powerhouse

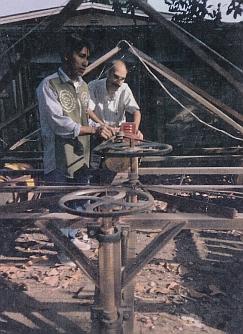

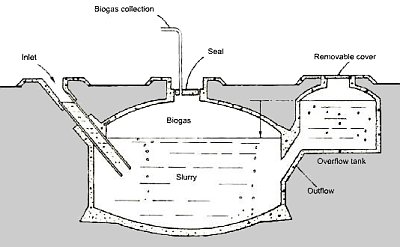

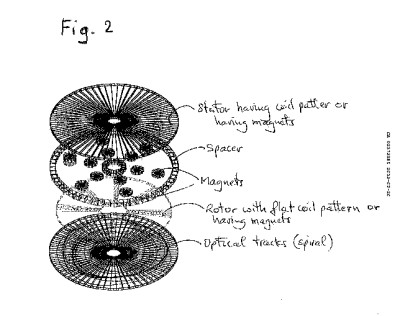

The manufacturing of a cross-flow turbine includes:

1) Cutting, shaping and welding metal plates

2) Machining supports for holding the rotor bearings - supports can be made by casting aluminum parts or by shaping metal parts

3) Building a rotor around an axle

4) Fitting and assembling parts

5) Excavating the canal and the powerhouse

6) Preparing the penstock which can be created using either existing recycled pipes, rolled metal plates or using PVC pipes

7) Building a small water dam, a gate and a metal grid to prevent debris from entering the water flow

8) Grain milling equipment powered by the turbine

9) The turbine, usually located below the powerhouse transmits its mechanical energy to any equipment attached to its pulley(s)

A turbine powering a mill at another location