Micro Hydropower Stations - 10 to 100 KW

Mechanical power in daytime, electricity at night

Training local entrepreneurs in the remotest corners of the globe to fabricate their own water turbines and build micro-hydropower projects between 10 to 100 KW is within reach. To achieve this, three elements are required: small flowing rivers, small metal workshops and more importantly motivated and creative human resources.

This challenge was taken by Soheyl Mottahedeh, an engineer and founder of SMI who lived for 20 years among villagers in RD Congo (ex-Zaire) and of Lao PDR to implement energy projects. Within a span of less than 6 months, young Congolese in Central Africa and Lao technicians in Southeast Asia learned to design and build their first water turbines, mobilise other villagers to build stone dams, excavate water canals, install penstocks and run their first mechanically driven grain-milling facilities at day time, and at night, run electrical generators to provide electricity through a rudimentary grid of hanging wires.

Once a few technicians learned how to design and implement a first hydropower scheme, the mystery "black box" syndrome was lifted and everything became possible. As a result, 20 villages in Kivu province of the Democratic Republic of Congo were able to built hydro-powered grain-milling stations in a period of less than 3 years, with 10 of these villages able to electrify. In a similar move, a few Lao technicians learned how to build their first water turbine (1990), before they were assigned by the government to replicate the technology to other villages.

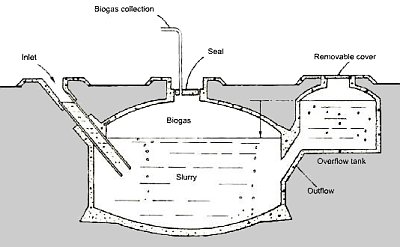

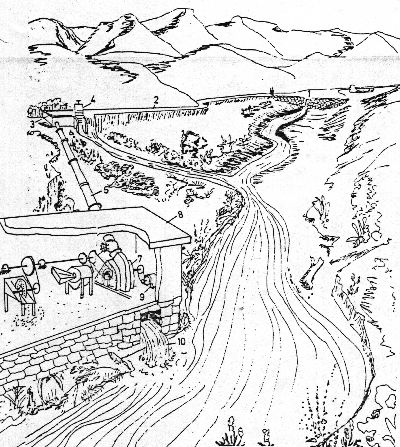

Layout of a micro hydropowered site for directing water into a cross-flow turbine that provides mechanical power operating agro-processing equipment at daytime and electricity at night.

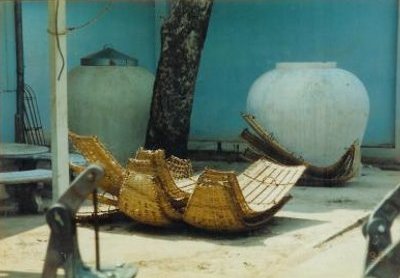

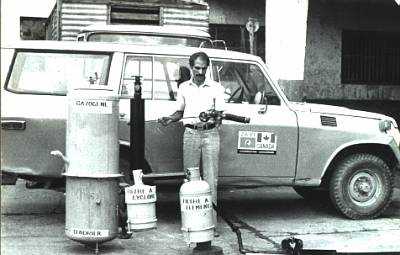

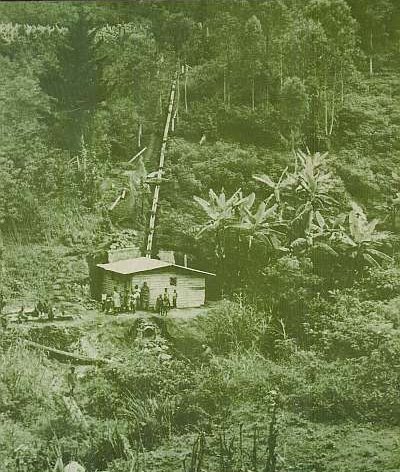

Soheyl's first micro-hydro site developed in 1986 near Bukavu in the eastern part of RDC Congo. Photo by Allen Inversin of NRECA.

N.B. Allen Inversin is the author of "Micro-Hydropower Sourcebook (A Practical Guide to Design and Implementation in Developing Countries)", NRECA International Foundation, Washington, DC.

Soheyl's Congolese company SODERZA became the recipient of a grant from ATI (Appropriate Technology International) to replicate micro-powered grain milling technology throughout Kivu Province, RDC Congo.

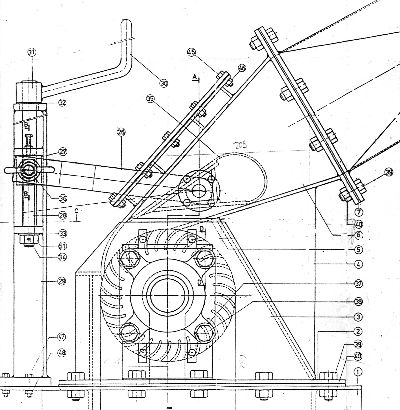

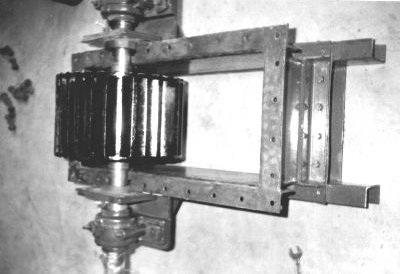

Turbine rotor

Various turbine rotor sizes

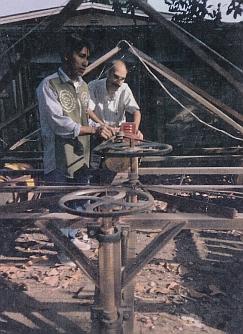

First Lao technicians trained in the manufacturing of water turbines